Pre-Engineered Steel Buildings: The Key to Sustainable Construction

The Problem of Growing Costs and Environmental Concerns

A factory owner in India recently faced a challenge that countless other business owners grapple with—growing demands and limited space. His business was expanding rapidly, and his existing facility was not equipped to handle the increased workload. The solution seemed obvious: build a new structure. But traditional construction posed significant obstacles—soaring costs, unpredictable project timelines, and increasing pressure to incorporate sustainable practices. Like many others, he had to juggle these competing priorities.

The pressure is not just a localized issue. Businesses across industries face these challenges. In manufacturing, logistics, and warehousing, the stakes are even higher because delays and disruptions have direct financial consequences. This is where the value of pre-engineered steel buildings (PEBs) comes into play. After extensive research and consultation, the factory owner discovered that PEBs could be a game-changer—not just for addressing his immediate needs but for creating a flexible, sustainable future.

In recent years, PEBs have proven their worth in transforming how businesses approach infrastructure and expansion. Companies like Metal Tree are at the forefront of this change, offering cost-effective and innovative pre-engineered steel building solutions to companies across India.

What Are Pre-Engineered Steel Buildings?

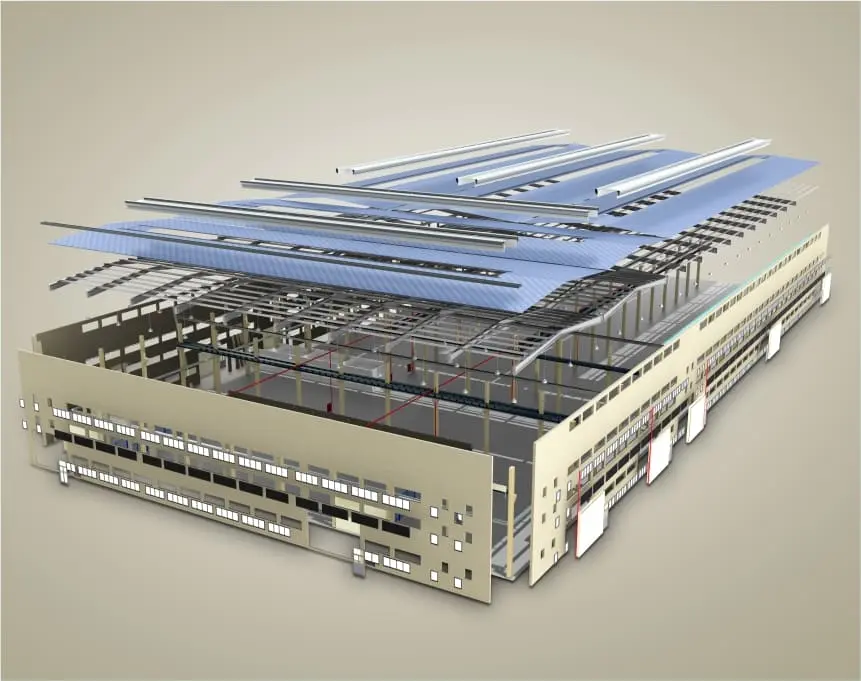

PEBs are pre-designed, factory-fabricated steel structures that are assembled on-site. They stand in contrast to traditional construction methods, where every part is built from scratch on-site. In PEBs, every component—from beams to columns—is engineered to fit precisely and assembled efficiently. This modular approach offers several key advantages, such as speed, affordability, and eco-friendliness.

But what makes these buildings stand out in today’s competitive market? It’s their ability to address common business pain points while providing long-term sustainability. Let’s dive into the specifics of why PEBs have become the go-to solution for businesses in various industries.

Advantages of Pre-Engineered Steel Buildings

1. Cost-Effectiveness: A Lifeline for Budget-Conscious Businesses

When planning construction projects, cost management is crucial. Traditional construction typically involves multiple variables that can cause expenses to spiral out of control. Unexpected labor shortages, escalating material costs, and project delays are all common factors that increase financial risk.

PEBs, on the other hand, offer a predictable and budget-friendly alternative. By using standard components and streamlined assembly processes, companies can reduce overall construction costs by 20-30%. The savings come from three key areas:

- Efficient Use of Resources: PEBs are designed and fabricated in a factory setting, reducing material waste.

- Lower Labor Requirements: Most of the labor-intensive tasks are performed off-site, minimizing on-site construction efforts.

- Shorter Project Timelines: Reduced construction times mean fewer labor hours and associated costs.

For instance, a mid-sized logistics company in India was facing budget constraints while planning the expansion of its storage facility. Traditional methods would have taken nearly 18 months to complete the project, and the projected costs were 35% over their budget. By opting for a pre-engineered steel building from Metal Tree, they not only saved money but also completed the project in under eight months, making a significant impact on their operational efficiency and bottom line.

"At Metal Tree, we believe that the future of construction is not just about building structures—it's about creating smarter, sustainable solutions that drive growth and innovation."

2. Time-Efficiency: Meeting Tight Deadlines with Minimal Downtime

In business, time is money. Delayed projects can lead to disrupted operations, lost opportunities, and reduced customer satisfaction. Traditional construction methods often require extensive on-site labor and coordination, which increases the likelihood of delays.

Pre-engineered steel buildings address this challenge by drastically reducing on-site construction time. On average, PEB projects take 50% less time to complete compared to conventional buildings. This efficiency results from the use of pre-fabricated components and a streamlined assembly process.

Consider a major retailer that needed to set up a new distribution center in response to growing demand. The company chose to work with Metal Tree to construct a pre-engineered steel building. What would typically take a year or more using traditional methods was completed in just six months. This allowed the retailer to open its distribution center ahead of schedule, improving its supply chain capabilities and customer satisfaction.

3. Sustainability: Building Responsibly for a Greener Future

Environmental sustainability is no longer a choice—it’s an imperative. Businesses are facing increasing pressure to adopt eco-friendly practices, not only to comply with regulations but also to meet customer expectations.

Pre-engineered steel buildings offer an environmentally responsible solution. Steel is a highly recyclable material, and the precise engineering involved in PEBs minimizes waste. Furthermore, the durability of steel structures means they have a longer lifespan and require fewer renovations or replacements over time. This reduces the overall environmental footprint of construction projects.

For example, a manufacturing company focused on green initiatives was looking to build a new production facility. By choosing a pre-engineered steel building, the company was able to reduce construction waste by nearly 50%, align with its sustainability goals, and receive positive feedback from environmentally conscious stakeholders.

Adapting to Business Needs: Flexibility and Scalability

One of the standout features of pre-engineered steel buildings is their adaptability. In a constantly evolving business landscape, flexibility is key to staying competitive. Whether it’s increasing production capacity, adding storage space, or reconfiguring a facility, PEBs offer the scalability needed to adapt to changing demands.

For instance, a tech company anticipating future growth opted for a pre-engineered steel building with provisions for future expansions. As their operations scaled up, the company could easily add more sections without disrupting ongoing activities. This flexibility not only saved time and money but also provided the agility needed to respond to market changes quickly.

Why Choose Metal Tree?

In India’s rapidly evolving construction landscape, Metal Tree has emerged as a leading provider of pre-engineered steel building solutions. The company’s success can be attributed to its commitment to quality, customer satisfaction, and innovation. By leveraging cutting-edge technology and maintaining strict quality standards, Metal Tree ensures that each project aligns with clients’ business goals and long-term needs.

One of the hallmarks of Metal Tree’s approach is its emphasis on customization. Every business has unique requirements, and Metal Tree works closely with its clients to provide tailored solutions. This collaborative approach has helped the company build a reputation for reliability and excellence in the industry.

Future Trends: The Growing Adoption of Pre-Engineered Steel Buildings

The rise of pre-engineered steel buildings is part of a broader trend toward more sustainable and efficient construction methods. According to market research, the global PEB market is expected to grow at a compound annual growth rate (CAGR) of 8.5% over the next decade. This growth is being driven by the increasing awareness of sustainable construction practices and the rising demand for cost-efficient solutions.

In India, the adoption of pre-engineered steel buildings is on the rise across sectors such as manufacturing, logistics, warehousing, and retail. As businesses recognize the benefits of PEBs, these structures are set to play an increasingly important role in shaping the future of the construction industry.

Key Takeaways: Why Pre-Engineered Steel Buildings Are the Future

- Affordability Without Compromise

PEBs offer a cost-effective solution for businesses looking to expand without sacrificing quality. The savings generated can be reinvested into growth initiatives, providing a competitive advantage. - Speed and Efficiency

Shorter construction timelines allow businesses to reduce downtime, avoid disruptions, and resume operations quickly. This efficiency translates into better customer service and increased profitability. - Sustainability

The use of steel makes PEBs a green choice. By reducing waste and improving energy efficiency, businesses can align with environmental goals and enhance their corporate reputation. - Flexibility and Scalability

Pre-engineered steel buildings provide the flexibility needed to expand or modify facilities as needed. This adaptability is especially valuable for businesses operating in dynamic industries.

The Future of Construction Is Here

As businesses seek more sustainable and efficient solutions, pre-engineered steel buildings are set to become a cornerstone of modern construction. They represent not only a smarter way to build but also a commitment to responsible growth. In a rapidly changing world, companies need infrastructure that can keep up with evolving demands and environmental challenges.

For business owners across industries, the question is no longer if they should adopt PEBs, but when. With companies like Metal Tree leading the way in India, businesses have a reliable partner to guide them through this transformation.

Conclusion: A Call to Action for Business Owners

If you’re a business owner grappling with rising construction costs, extended timelines, or mounting environmental concerns, it’s time to explore the benefits of pre-engineered steel buildings. Whether you need to expand your existing facility, build a new warehouse, or establish a manufacturing unit, PEBs offer the perfect blend of affordability, speed, and sustainability.

Reach out to Metal Tree to learn more about how pre-engineered steel buildings can revolutionize your construction plans and set your business on a path to growth and success.

3 thoughts on “Pre-Engineered Steel Buildings: The Key to Sustainable Construction”

Add a Comment Cancel reply

All Categories

Recent Posts

Why Are PEB Structures Ideal for Industrial Applications?

What Types of Pre-Engineered Buildings Are Used Across Different Industries?

Tags

Call Us at

+91 9311624628

[…] constraints, which if not handled precisely can jeopardize the entire endeavor. In this scenario, pre-engineered steel buildings not only alleviate the issues but also offer numerous advantages such expeditious construction, cost […]

[…] goals of speed, cost, efficiency, and durability are no longer optional; they're paramount. Pre-engineered steel construction is able to meet these requirements […]

[…] constraints, which if not handled precisely can jeopardize the entire endeavor. In this scenario, pre-engineered steel buildings not only alleviate the issues but also offer numerous advantages such expeditious construction, cost […]