Pre-Engineered Building Manufacturer: Complete Guide to Industrial Shed Construction

Key Takeaway: Investing in a thoughtfully designed industrial shed through Pre-Engineered Buildings (PEB) can save manufacturing and logistics firms in India up to 30% in time and 20% in costs while ensuring structural reliability and future scalability. The only step you need to take is to choose the right Pre-Engineered Building Manufacturer that understands you and your business requirements and offers you what you deserve. Let's Explore...

Introduction

Imagine a manufacturing company in Pune facing escalating overheads, delayed timelines, and unexpected cost overruns while constructing a traditional steel-framed factory shed. Or consider a logistics firm in Chennai grappling with inefficient layouts that disrupt supply chains and inflate operational expenses. These real-world challenges spotlight a pressing need: faster, cost-effective, and tailor-made industrial sheds. Enter Metal Tree’s Pre-Engineered Buildings (PEB) solution—an approach that’s reshaping how Indian businesses build for growth.

Pre-Engineered Buildings, or PEB, utilize factory-manufactured components engineered to precise specifications. Unlike conventional construction, PEB sheds arrive at the site ready for quick assembly. For business owners in India seeking to optimize budgets and timelines, PEB offers a strategic advantage: accelerated project delivery without compromising on quality or future expansion.

1. Understanding Pre-Engineered Buildings (PEB)

What Are Pre-Engineered Buildings?

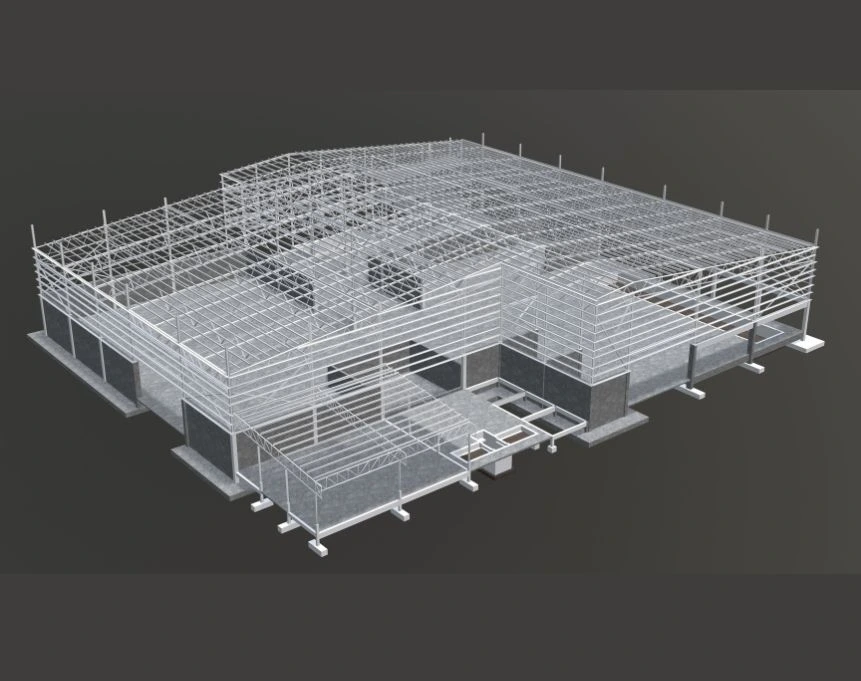

Pre-Engineered Buildings consist of primary and secondary framing members fabricated from high-strength steel. These components—columns, rafters, purlins, and wall panels—are predesigned in a factory environment and shipped to the construction site. Metal Tree, a leading PEB provider in India, custom-engineers each structure based on load calculations, environmental factors, and client requirements.

Core Advantages of PEB

- Speed of Construction

Factory fabrication slashes on-site work by up to 50%. Components arrive pre-cut, drilled, and ready to bolt together, enabling completion in weeks instead of months. - Cost Efficiency

Repetitive manufacturing processes reduce material waste. On-site labor demand declines, cutting labor costs by up to 20%. - Customization & Flexibility

Whether you need a wide-span shed for heavy machinery or a multi-bay warehouse, PEB designs adapt seamlessly. Future expansions involve adding bays rather than reconstructing the entire building. - Structural Reliability

Precision engineering ensures consistent quality and compliance with Indian building codes. PEB components pass rigorous quality checks in controlled factory conditions. - Sustainability

High-strength steel is recyclable. Metal Tree’s PEB systems minimize carbon footprint through optimized fabrication and reduced on-site waste.

2. Pre-Construction Planning

Successful industrial shed construction begins long before steel hits the ground. Effective planning addresses site requirements, regulatory approvals, budget constraints, and design objectives.

2.1 Site Assessment and Soil Investigation

A detailed site survey and geotechnical study reveal soil bearing capacity, groundwater levels, and potential obstructions. For instance, a logistics firm planning a cold storage facility in Gujarat must consider soil moisture content and frost depth to select the right foundation type—pad footings, raft slabs, or pile foundations.

2.2 Regulatory Approvals and Clearances

Securing municipal permits and environmental clearances can take 4–8 weeks. Metal Tree’s engineering team streamlines this process by preparing structural drawings, load calculations, and Storm Water Drainage (SWD) plans compliant with the National Building Code of India.

2.3 Budgeting and Value Engineering

Clients often face budget overruns due to design changes mid-project. Incorporating value engineering early—analyzing materials and structural layouts to maintain performance at lower cost—can keep the project on track. For example, opting for insulated sandwich panels instead of thicker single-skin sheets can reduce energy expenses by 25% over the building’s lifecycle.

3. Design & Engineering

3.1 Structural Modeling

Using advanced 3D Finite Element Analysis (FEA) software, Metal Tree engineers simulate wind loads, seismic forces, and roof live loads. In Ludhiana, where wind speeds can reach 50 m/s, structures are designed with additional stiffeners and wind-bracing systems.

3.2 Material Selection

- Primary Frames: High-tensile Z-sections or I-beams coated with corrosion-resistant zinc.

- Secondary Members: Light gauge C and Z purlins for roof support.

- Roofing & Cladding: Galvalume sheets, insulated sandwich panels, or polycarbonate skylights for natural illumination.

3.3 Load Calculations

Load tables for snow, wind, and equipment weight are meticulously tabulated. A cold storage plant in Himachal Pradesh, for example, requires higher snow load parameters than a dry warehouse in Mumbai. Accurate load analysis prevents structural failures and expensive retrofits.

4. Fabrication Process

4.1 Factory Workflow

Factory fabrication follows a four-stage process:

- Cutting: CNC-driven machines cut steel plates and sections to exact dimensions.

- Punching & Drilling: Automated punching ensures bolt holes align precisely.

- Welding & Assembly: Robotic welders create consistent weld quality, while manual checks maintain certifications.

- Surface Treatment: Shot blasting and zinc-phosphate coating enhance corrosion resistance.

4.2 Quality Control

Quality inspectors conduct Non-Destructive Testing (NDT) on welds and verify dimensional tolerances within ±0.5 mm. Material traceability tags link each component to its mill test certificate.

4.3 Packaging & Logistics

Once fabricated, components are bundled, tagged, and shipped on flat-rack containers or standard trailers. Metal Tree’s distribution network spans 15 major Indian ports, ensuring on-time deliveries even to remote industrial parks in Orissa or Assam.

5. Site Preparation & Foundation

5.1 Earthwork & Grading

Leveling the site within ±10 mm is critical for structural alignment. Laser-guided graders achieve precision quickly, reducing rework.

5.2 Foundation Construction

- Pad Footing: Ideal for light to moderate loads; concrete grade M25 with 20 mm aggregate ensures durability.

- Raft Foundation: Employed for poor soil; thick reinforced slabs distribute loads evenly.

- Pile Foundation: Necessary when bearing stratum lies deep; bored cast-in-situ piles transfer loads to stable layers.

5.3 Anchor Bolt Installation

Anchor bolts are cast in concrete based on bolt layout drawings. Accurate casting is crucial—misaligned bolts can delay erection or necessitate costly corrections.

6. Erection & Assembly

6.1 Pre-Assembly Inspection

Before on-site erection, Metal Tree’s supervisors cross-verify component tags, bolt sizes, and erection drawings. Any discrepancies trigger immediate corrective action.

6.2 Structural Erection Sequence

- Column Placement: Crane-lifted columns are set on anchor bolts and temporarily braced.

- Rafter Connection: Primary rafters join columns using high-strength bolts (grade 10.9).

- Bracing & Purlin Installation: Wind bracings ensure lateral stability, followed by laying C/Z purlins.

- Roof & Wall Cladding: Panels are fixed with self-drilling screws; sealants and EPDM gaskets safeguard against leaks.

6.3 Safety Protocols

Strict adherence to OSHA‐equivalent safety norms in India. Erection teams use harnesses with minimum tensile strength of 2 kN and conduct daily safety briefings.

7. Mechanical, Electrical & Plumbing (MEP) Integration

7.1 Overhead Crane Systems

For heavy manufacturing, integrated crane rails are installed on top of rafters. Rails are leveled within 1 mm over a 10 m span to ensure smooth trolley travel.

7.2 HVAC & Ventilation

Natural ventilation through ridge ventilators and sidewall louvers often suffices. In dust-sensitive operations, positive‐pressure filtered air systems maintain indoor air quality.

7.3 Electrical Installations

Lighting layouts leverage high‐bay LED fixtures at 20 lx for industrial floors, reducing energy consumption by 40% compared to fluorescent alternatives.

7.4 Plumbing & Drainage

Rainwater harvesting systems and French drains are integrated into building design for sustainable water management.

8. Finishing Touches & Commissioning

8.1 Insulation & Thermal Comfort

In hot climates like Tamil Nadu, roof insulation with 50 mm polyurethane foam can lower internal temperatures by up to 8 °C, boosting worker comfort and reducing HVAC loads.

8.2 Fire Safety & Regulatory Compliance

Fire‐rated shutters, smoke detectors, and emergency exits are installed per National Building Code requirements. Fireproof coatings on steel members add another safety layer.

8.3 Final Inspections & Handover

A detailed Punch List of minor defects—misaligned panels, loose fasteners—is addressed. Upon completion, Metal Tree issues a Completion Certificate, indemnifying structural integrity and compliance.

9. Post-Construction Considerations

9.1 Maintenance & Lifecycle

Scheduled inspections every six months detect corrosion or bolt loosening early. Touch-up painting and sealant replacement prolong the building’s service life beyond 30 years.

9.2 Future Expansion

PEB systems are inherently modular. Adding extra bays or mezzanine floors requires minimal disruption—new frames slot into existing bracing locations.

9.3 Sustainability Reporting

For firms pursuing green certifications, Metal Tree provides Life Cycle Assessment (LCA) reports detailing embodied carbon and material recyclability.

Conclusion

For Indian manufacturing and logistics businesses seeking swift, cost-effective, and reliable industrial shed solutions, Metal Tree’s Pre-Engineered Buildings stand out as a future-proof investment. By integrating meticulous planning, cutting-edge fabrication, precise erection, and robust maintenance strategies, PEB sheds deliver unmatched value and adaptability. Whether building a heavy-duty factory, expansive warehouse, or climate-controlled facility, embracing PEB can reduce time-to-market by half and optimize long-term operational costs—all while ensuring structural excellence and sustainability.

FAQ

1. What are the benefits of choosing a Pre-Engineered Building Manufacturer for industrial shed construction?

Pre-Engineered Building Manufacturers offer faster construction, cost savings, high-quality materials, and customizable designs that ensure durability and efficiency for industrial sheds in India.

2. How long does it take to complete an industrial shed with a Pre-Engineered Building Manufacturer?

Industrial shed construction with a reputable Pre-Engineered Building Manufacturer generally takes 30% to 40% less time compared to traditional methods due to advanced engineering and factory-built components.

3. Are pre-engineered industrial sheds suitable for different industries in India?

Yes, pre-engineered industrial sheds are ideal for manufacturing, warehousing, logistics, agriculture, and other sectors, thanks to their flexibility, scalability, and robust performance.

4. How can I ensure my industrial shed is environmentally sustainable?

Partnering with a top PEB manufacturer enables the use of eco-friendly materials and designs that incorporate energy efficiency, waste minimization, and sustainable practices.

5. What factors influence the cost of an industrial shed from a Pre-Engineered Building Manufacturer?

Costs depend on shed size, design specifications, location, material choices, and added customization, with pre-engineered options offering better cost control and transparency.

Follow us on:

All Categories

Recent Posts

Why Are PEB Structures Ideal for Industrial Applications?

What Types of Pre-Engineered Buildings Are Used Across Different Industries?

Tags

Call Us at

+91 9311624628