Cost-Effective Warehouse Construction: Reduce Build Time and Total Project Cost

Every year, thousands of logistics companies, e-commerce businesses, and manufacturing facilities across India face the same challenge: building a warehouse quickly without breaking the budget. The pressure is real. Delays mean missed revenue opportunities. Cost overruns eat into profit margins. And the traditional construction methods? They're painfully slow—taking six to nine months just to get four walls and a roof in place.

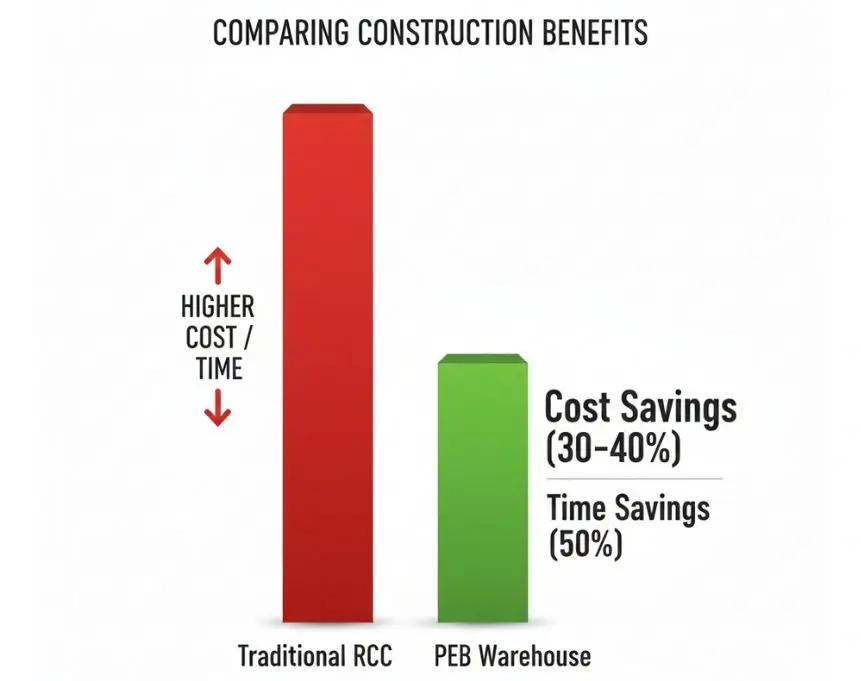

Here's the good news: there's a better way to build. Pre-engineered warehouse buildings have revolutionized how businesses approach industrial construction. Instead of pouring concrete and waiting weeks for it to cure, modern warehouse solutions can be operational in just 8 to 12 weeks. Better still, these cost-effective warehouse construction methods cut your total project costs by 30 to 40 percent compared to conventional RCC buildings.

In this guide, we'll explore actionable strategies to reduce warehouse construction costs and timelines without compromising quality or durability. Whether you're building your first warehouse or expanding an existing operation, understanding these cost reduction tactics will help you make smarter decisions about your construction investment.

Why Building Speed Matters More Than You Think

When people discuss warehouse construction costs, they usually focus on materials and labor. But here's what many miss: the hidden expenses that pile up while you're waiting for your building to be completed.

Consider this scenario: a logistics company needs a 20,000 square foot distribution center. With traditional RCC construction, the project takes 24 to 36 weeks. During those six to nine months, they're paying for site management, equipment rentals, supervision, and temporary utilities. They're also missing out on revenue that the operational warehouse would generate. Meanwhile, their financing costs continue to accumulate—costing them approximately Rs16.7 lakhs per month in interest on a Rs2 crore facility.

Now compare that to a cost-effective warehouse using pre-engineered building technology. The same facility is ready in just 8 to 12 weeks. That's a 12-16 week acceleration that translates into real money: Rs50 to Rs80 lakhs in financing savings alone, plus Rs8 to Rs12 lakhs in reduced site management overhead, plus Rs10 to Rs20 lakhs in operational revenue that starts flowing in earlier. The speed advantage isn't just convenient—it's financially transformational.

Understanding Construction Timelines: PEB vs. Traditional Methods

To appreciate how much time you can save, let's break down the construction timeline for both methods.

Traditional RCC Warehouse Construction Timeline

| Phase | Duration | Details |

| Design & Engineering | 4-8 weeks | Architectural drawings, structural design, approvals |

| Site Preparation | 4-8 weeks | Ground leveling, foundation trenching, utility setup |

| Foundation & Curing | 6-8 weeks | Concrete pouring, minimum 14-28 day cure time |

| Structural Erection | 6-10 weeks | Column placement, beam installation, reinforcement |

| Finishing Work | 5-8 weeks | Roofing, flooring, painting, installations |

| Total Duration | 24-36 weeks | 6-9 months |

Traditional construction is sequential—each phase waits for the previous one to complete. Weather disruptions, material delays, and labor availability issues frequently extend timelines further.

Pre-Engineered Warehouse Construction Timeline

| Phase | Duration | Details |

| Design & Approvals | 1-4 weeks | Standardized design selection, minimal engineering needed |

| Site Preparation | 1-2 weeks | Simpler foundation requirements |

| Fabrication (Parallel) | 4-8 weeks | Factory manufacturing occurs while site prep happens |

| Assembly & Finishing | 2-3 weeks | On-site bolting, installation, final setup |

| Total Duration | 8-15 weeks | 2-3.5 months |

The key difference? Parallel processing. While your site is being prepared, the warehouse components are being manufactured in a controlled factory environment. This overlap compresses your overall timeline dramatically

The Cost Breakdown: Where You Actually Save Money

Now let's talk about what matters to your bottom line—the actual cost savings. Here's where the PEB advantage becomes crystal clear.

Material Cost Optimization

Cost-effective warehouse construction starts with smarter material usage. PEB designs employ optimized steel sections and load-path engineering that reduces overall steel quantity by 15 to 25 percent compared to conventional designs. Factory fabrication with precision CNC machining minimizes material waste to just 2 to 5 percent, while traditional site-based construction generates 15 to 20 percent waste.

For a 20,000 square foot facility, this translates to:

- Steel reduction: Rs36 to Rs48 lakhs in savings

- Waste elimination: Rs12 to Rs20 lakhs in savings

- Total material advantage: Rs48 to Rs68 lakhs per project

Labor Cost Reduction

This is where budget warehouse solutions truly shine. PEB assembly requires primarily skilled bolting work rather than continuous welding, specialized concrete work, and form-building. A 20,000 square foot warehouse needs:

- PEB approach: 2,000 to 2,500 labor-days at Rs500-Rs700/day = Rs10 to Rs17.5 lakhs

RCC approach: 6,000 to 8,000 labor-days at Rs800-Rs1,200/day = Rs48 to Rs96 lakhs - Labor savings: Rs31 to Rs79 lakhs

The reduction in labor dependency is particularly valuable in India's construction market, where skilled welders and concrete specialists command premium rates and aren't always readily available.

Schedule-Related Savings

Every week your project runs longer, you're paying for equipment rental, site management, supervision, and utilities. For a typical warehouse:

- Equipment rental savings: 12-week acceleration = Rs67 to Rs126 lakhs saved

- Site overhead reduction: Rs25 to Rs42 lakhs saved

- Contingency reserve reduction: 5-10% additional capital released

Combined, these schedule advantages represent 8 to 15 percent of your total project cost.

Complete Cost Comparison

Here's the comprehensive picture for a functional warehouse in India (2025 pricing):

| Cost Category | PEB (Rs/sq ft) | RCC (Rs/sq ft) | Savings |

| Materials | Rs300-Rs450 | Rs400-Rs550 | Rs20-40 lakhs |

| Labor | Rs150-Rs250 | Rs400-Rs600 | Rs50-70 lakhs |

| Equipment & Overhead | Rs100-Rs150 | Rs200-Rs300 | Rs20-30 lakhs |

| Schedule/Financing | Rs150-Rs200 | — | Rs30-40 lakhs |

| Total per Sq Ft | Rs900-Rs1,600 | Rs 1,400-Rs2,200 | Rs120-180 lakhs (30-40% savings) |

For a 20,000 square foot warehouse, you're looking at total project cost savings of Rs1.2 to Rs1.8 crore.

The Quality Question: Isn't Cheaper Construction Lower Quality?

This is the objection we hear most often, and it's worth addressing directly. The assumption that reduce construction costs means reduce quality is based on a fundamental misunderstanding of how pre-engineered buildings work.

The truth is this: factory-controlled manufacturing produces superior quality compared to site-based construction. Period.

Why PEB Quality Exceeds Traditional Methods

When your warehouse is built in a factory, every component undergoes rigorous quality control:

- Raw material inspection: Steel is verified against IS 2062 and ASTM standards before fabrication begins

- Precision machining: CNC equipment maintains ±1-2mm tolerances, eliminating measurement errors

- Automated welding: Robotic systems deliver consistent weld penetration superior to manual field welding

- Coating systems: Factory epoxy and polyurethane application achieves 120-150 micron thickness versus 50-80 microns in field application

- Post-fabrication testing: Load testing and ultrasonic inspection catch defects before delivery

This manufacturing rigor produces structural integrity comparable to premium traditional construction, but at lower cost. You're not sacrificing quality—you're leveraging manufacturing efficiency.

How Long Will It Actually Last?

PEB warehouses achieve 25 to 50 year operational lifespans with proper maintenance—equivalent to conventional RCC buildings. The high-strength steel, corrosion-resistant coatings, and bolted connections withstand:

- Harsh weather: Monsoons, extreme temperatures, industrial exposure

- Seismic events: Flexible steel frames outperform rigid RCC under earthquake stress (meets IS 1893 standards)

- Wind loads: Cyclone-resistant design prevents catastrophic failure

- Pest and corrosion: Naturally resistant to termites and rust (25-30 year coating life)

The real-world evidence is compelling: PEB structures built 25 years ago across India continue operating with minimal maintenance and no structural concerns.

Seven Specific Strategies to Further Reduce Warehouse Construction Costs

Beyond the inherent PEB advantage, here are actionable tactics to cut costs even further:

1. Choose Standardized Design Over Custom Engineering

Custom warehouse designs require 4-8 weeks of engineering and add Rs50,000 to Rs100,000 in fees. Standardized layouts (30x40, 40x60, 50x80 configurations) are pre-engineered and approved, eliminating design costs entirely while accelerating permit approval by 2-4 weeks.

Savings: Rs50,000-Rs100,000 + Rs5-Rs10 lakhs in financing acceleration.

2. Leverage Pre-Fabrication Component Inventories

Manufacturers who maintain inventory of standard components achieve 15-25 percent economies of scale. Projects built from available stock cost significantly less than fully custom fabrications.

Savings: Rs30-Rs50 lakhs per facility.

3. Optimize Clear Height Within Structural Capability

Increasing from 24 feet to 36 feet clear height (within PEB structural capacity) boosts storage density by 20-25 percent with only Rs50-Rs100 per sq ft additional structural cost. This design optimization improves annual revenue by Rs6-Rs12 lakhs for distribution operations.

Savings: Rs6-Rs12 lakhs in annual operational revenue improvement.

4. Integrate Energy-Efficient Envelope Systems

Insulated sandwich panels (PUF, EPS, ROCKWOOL) reduce cooling/heating costs by 15-30 percent in temperature-controlled warehouses. Government subsidies offset 30 percent of solar integration costs.

Savings: Rs2-Rs5 lakhs annually in utilities + Rs1.8-Rs2.1 lakhs in subsidies.

5. Plan for Phased Expansion

Build 10,000 sq ft initially, then expand as demand grows. Phased development reduces upfront capital by 40-50 percent and improves early-stage ROI by 200-300 basis points compared to building full capacity upfront.

Advantage: Earlier ROI from initial phase (18-24 months vs. 36-48 months).

6. Minimize Labor Management Overhead

Engage contractor organizations rather than aggregating individual workers. Reduces recruitment, training, and supervision overhead by 15-20 percent.

Savings: Rs5-Rs15 lakhs in management costs.

7. Factor in Long-Term Maintenance Advantages

30-year maintenance costs for PEB warehouses (Rs2-Rs4 lakhs) are substantially lower than RCC buildings (Rs8-Rs12 lakhs). This 5-8 percent lifetime cost advantage should influence your construction method selection.

Long-term advantage: Rs4-Rs8 lakhs total maintenance savings over building life.

Addressing Common Concerns

"Can't I customize a PEB warehouse?

Modern PEB design systems support 85-95 percent of warehouse requirements without custom engineering. When customization is required, marginal engineering cost (Rs2,000-Rs5,000) is negligible relative to project scale.

Are bolted connections reliable long-term?

High-tensile bolts with self-locking washers maintain integrity for decades. Annual inspections (Rs5,000-Rs10,000) ensure continued performance. Corrosion resistance is superior when bolts are galvanized.

Can I expand a PEB warehouse later?

Yes. Modularity makes additions easier than in RCC buildings. Adding bays requires no structural redesign or facility closure—a significant operational advantage.

How to Get Started With Cost-Effective Warehouse Construction

- Define your requirements (size, height, load capacity, special features)

- Compare three qualified PEB manufacturers with competitive quotations

- Request preliminary designs and timeline proposals

- Evaluate total cost of ownership, not just upfront construction cost

- Engage your selected partner for detailed design and engineering

- Plan your implementation roadmap with parallel site preparation and manufacturing

- Commence construction with confidence in your timeline and budget

Conclusion

Cost-effective warehouse construction isn't about cutting corners. It's about building smarter. Pre-engineered warehouse buildings deliver proven advantages across three dimensions: faster timelines, lower capital costs, and superior long-term value. When you factor in the financing savings, operational revenue acceleration, and reduced maintenance expenses, the financial case becomes overwhelming.

At Metal Tree, we've designed and delivered PEB warehouse solutions across India for over a decade. From cold storage facilities to e-commerce fulfillment centers to agricultural godowns, we understand what warehouse operators need: buildings that are fast to construct, affordable to build, and durable enough to serve for decades without excessive maintenance. If you're evaluating warehouse construction options, don't rely solely on conventional methods. Explore how pre-engineered building technology can transform your project timeline and budget.

Frequently Asked Questions

A: Typically 20-40% cost reduction (Rs50-Rs80 per square foot savings). For a 20,000 sq ft facility, that's Rs1-Rs1.6 crore in direct savings, plus additional financing and overhead savings.

A: Depending on size and complexity, most facilities are completed in 8-12 weeks—compared to 24-36 weeks for traditional RCC construction. This 12-16 week acceleration translates into Rs50-Rs80 lakhs in financing cost savings.

A: Yes. PEB structures achieve 25-50 year operational lifespans with proper maintenance. Factory-controlled manufacturing ensures superior quality consistency compared to site-built alternatives. They exceed IS 1893 earthquake standards and IS 2062 material specifications.

A: Absolutely. Most requirements are accommodated within standardized designs. When customization is needed, marginal engineering costs are minimal compared to the overall project value.

A: Minimal. Annual inspections and biannual gutter cleaning are typical. Long-term maintenance costs (Rs2-Rs4 lakhs over 30 years) are substantially lower than RCC buildings (Rs8-Rs12 lakhs).

Ready to Build Your Next Warehouse?

At Metal Tree, we specialize in delivering innovative, durable, and cost-effective pre-engineered warehouse buildings designed for quick assembly and tailored to your operational needs. Whether you need cold storage, retail warehousing, e-commerce fulfillment, or industrial storage, our team of experienced engineers and project managers ensures precision and quality at every step.

Contact Metal Tree today to discuss your warehouse project. Request a custom quote and discover how we can help you reduce both construction timelines and total project costs.

Let's transform your warehouse vision into reality with speed, strength, and significant savings.

📞 Call us today

+91 93116 24628

📧 Email your inquiry

info@metaltree.in

All Categories

Recent Posts

Cost-Effective Warehouse Construction: Reduce Build Time and Total Project Cost

Why Are PEB Structures Ideal for Industrial Applications?

Tags

Call Us at

+91 9311624628