Cost Savings of Pre-Engineered Buildings in Commercial Construction

Introduction

In today’s competitive business landscape, the success of a commercial construction project hinges not just on aesthetics or durability, but on the bottom line. With land prices rising, material costs fluctuating, and labor availability becoming increasingly uncertain, cost control has become more critical than ever.

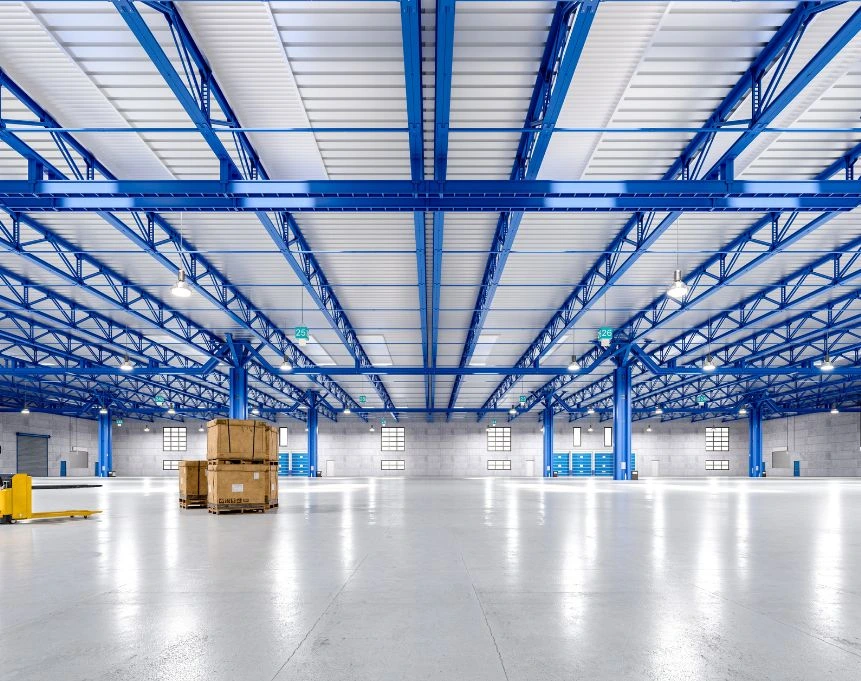

For businesses and developers looking to maximize value, pre-engineered buildings (PEBs) offer a powerful solution. Known for their speed, precision, and scalability, PEBs are now being recognized for another major benefit-cost savings.

In this blog, we’ll explore how pre-engineered buildings reduce expenses in commercial construction, and we’ll break down the real-world factors contributing to PEB affordability. Whether you're planning a retail outlet, a multi-story office, or a hospitality space, understanding the construction cost reduction potential of PEBs can transform your project strategy.

Want to save money without compromising quality? Keep reading to learn how PEBs deliver smarter, leaner commercial building solutions.

1. What Are Pre-Engineered Buildings (PEBs)?

Pre-engineered buildings are structural systems where all components, frames, panels, bolts, and finishes, are designed and fabricated in a factory, then assembled on-site. This model eliminates unpredictable variables, reducing time and cost during construction.

PEBs typically include:

- Primary steel frames (columns, rafters)

- Secondary members (purlins, girts)

- Roof and wall sheeting

- Insulation, fasteners, and accessories

Their flexibility makes them ideal for commercial construction projects like malls, hotels, showrooms, and office complexes.

2. Understanding Commercial Construction Costs

Before diving into savings, it's important to understand what drives costs in a typical commercial project:

- Materials: Cement, steel, bricks, glass, insulation, etc.

- Labor: Skilled and unskilled workers for various tasks

- Time: Longer timelines increase indirect costs like site rentals and loan interest

- Rework and Delays: Weather issues, labor strikes, or material shortages

- Design Complexity: Unique layouts or customizations require more time and effort

PEBs address many of these challenges by creating a controlled, streamlined construction process, leading to significant savings.

3. Core Areas of Cost Savings in PEBs

Here’s how cost savings from pre-engineered buildings are realized across various stages of construction:

A. Faster Completion

PEBs can reduce build time by up to 50%, resulting in lower site management costs and quicker revenue generation.

B. Material Optimization

PEBs are designed for optimal material use, with little to no wastage. This leads to better cost-efficiency.

C. Labor Efficiency

Factory-fabricated components require less on-site labor, cutting down wage bills significantly.

D. Minimal Rework

With high-precision manufacturing and quality checks, errors and rework costs are minimized.

E. Reduced Equipment Hire

Shorter on-site time reduces crane hire, scaffolding, and machinery rental expenses.

Together, these factors create a leaner budget structure for your commercial build.

4. PEB Affordability: Factors That Reduce Project Spend

Let’s break down what makes PEB affordability such a strong value proposition:

- Standardization: Pre-engineered components reduce the cost of customization.

- Bulk Manufacturing: Factory-scale production benefits from economies of scale.

- Quick Assembly: Bolt-based systems reduce the need for skilled masons or carpenters.

- Integrated Design: Structural, architectural, and MEP elements can be coordinated earlier, avoiding costly design clashes.

This makes PEBs ideal for:

- Startup office buildings

- Mid-sized commercial complexes

- Franchised retail chains

- Hospitality chains seeking rapid rollout

5. Time Equals Money: The Efficiency Advantage

Commercial projects typically depend on early occupancy or leasing to start generating income. Every month lost to construction delays is revenue lost.

With PEBs:

- Retail stores can launch faster, especially during peak seasons.

- Office spaces can be rented out sooner, increasing ROI.

- Hotels or banquet halls can start bookings earlier.

By reducing construction time by weeks or even months, PEBs offer not just cost savings but early revenue advantage, something traditional systems often can’t match.

6. Construction Cost Reduction Compared to RCC

Let’s compare key cost parameters of PEBs and RCC (Reinforced Cement Concrete) structures:

| Parameter | PEB | RCC |

| Construction Time | 2–4 months | 6–10 months |

| Material Wastage | Minimal | Moderate to High |

| On-Site Labor Cost | Low | High |

| Equipment Rental Duration | Short | Long |

| Rework/Delays | Rare | Common |

| Cost Overruns | Unlikely | Frequent |

These differences make PEBs a more predictable and efficient commercial building solution - with up to 20–30% cost reduction in many cases.

7. Case Study: PEBs in a Real-World Commercial Project

A retail chain wanted to roll out 10 showrooms across North India in under 6 months. By using pre-engineered buildings, they:

- Completed each store in under 10 weeks

- Saved 25% on average construction costs

- Standardized designs to reduce architectural fees

- Opened 2 months ahead of schedule—boosting early revenue

This shows how construction cost reduction with PEBs translates directly into real business benefits.

8. Long-Term Value and ROI

While initial savings are significant, PEBs also offer long-term financial advantages:

- Lower Maintenance: Steel structures require less upkeep than RCC buildings

- Energy Efficiency: Insulated panels reduce HVAC costs

- Adaptability: Easy modifications or expansions minimize future capex

- Durability: Steel resists pests, weather, and aging better, reducing lifecycle costs

When you evaluate total cost of ownership, PEBs often outperform traditional buildings by a large margin.

Commercial construction doesn’t have to break the bank. At Metal Tree, we engineer pre-engineered buildings that cut costs, save time, and deliver long-term value without compromising on quality.

9. Conclusion

If you’re planning a commercial project in today’s fast-moving environment, you need a solution that balances speed, quality, and affordability. That’s exactly what pre-engineered buildings deliver.

By significantly reducing construction time, minimizing labor and material costs, and simplifying design and project management, PEBs offer clear and measurable cost savings without compromising on structural integrity or aesthetic appeal.

Ready to make your commercial construction more cost-effective?

Contact Metal Tree for expertly engineered, affordable PEB systems that meet your project goals and budget.

10. FAQs

1. How do pre-engineered buildings reduce commercial construction costs?

By minimizing material waste, shortening timelines, and requiring less labor, PEBs reduce both direct and indirect costs.

2. Are PEBs cheaper than concrete buildings?

In many cases, yes. PEBs can offer 20–30% cost savings due to efficiency in design, assembly, and project management.

3. Are pre-engineered buildings suitable for multistorey commercial structures?

Yes, modern PEBs are fully customizable and can be used for multi-storey retail, office, or hospitality projects.

4. What is the ROI for PEB-based commercial buildings?

With faster occupancy and lower operating costs, PEBs often deliver higher ROI than traditional construction.

5. Can PEBs be designed to match premium aesthetics?

Absolutely. PEBs support architectural customization, including glass facades, wood finishes, and more.

Follow us on:

2 thoughts on “Cost Savings of Pre-Engineered Buildings in Commercial Construction”

Add a Comment Cancel reply

All Categories

Recent Posts

Why Are PEB Structures Ideal for Industrial Applications?

What Types of Pre-Engineered Buildings Are Used Across Different Industries?

Tags

Call Us at

+91 9311624628

[…] Commercial construction in India is booming-but not without its problems: […]

[…] efficiency and cost savings with strategic Pre-Engineered Building Designs – pre-engineered buildings (PEBs) are transforming […]